Starting with ERP software for manufacturing, this introductory paragraph aims to provide a captivating overview of how this software revolutionizes operations in the manufacturing industry. From enhancing productivity to optimizing processes, ERP software plays a crucial role in the success of manufacturing businesses.

As we delve deeper into the functionalities and benefits of ERP software tailored for manufacturing, it becomes evident how crucial this technology is for driving growth and competitiveness in the industry.

Overview of ERP Software for Manufacturing

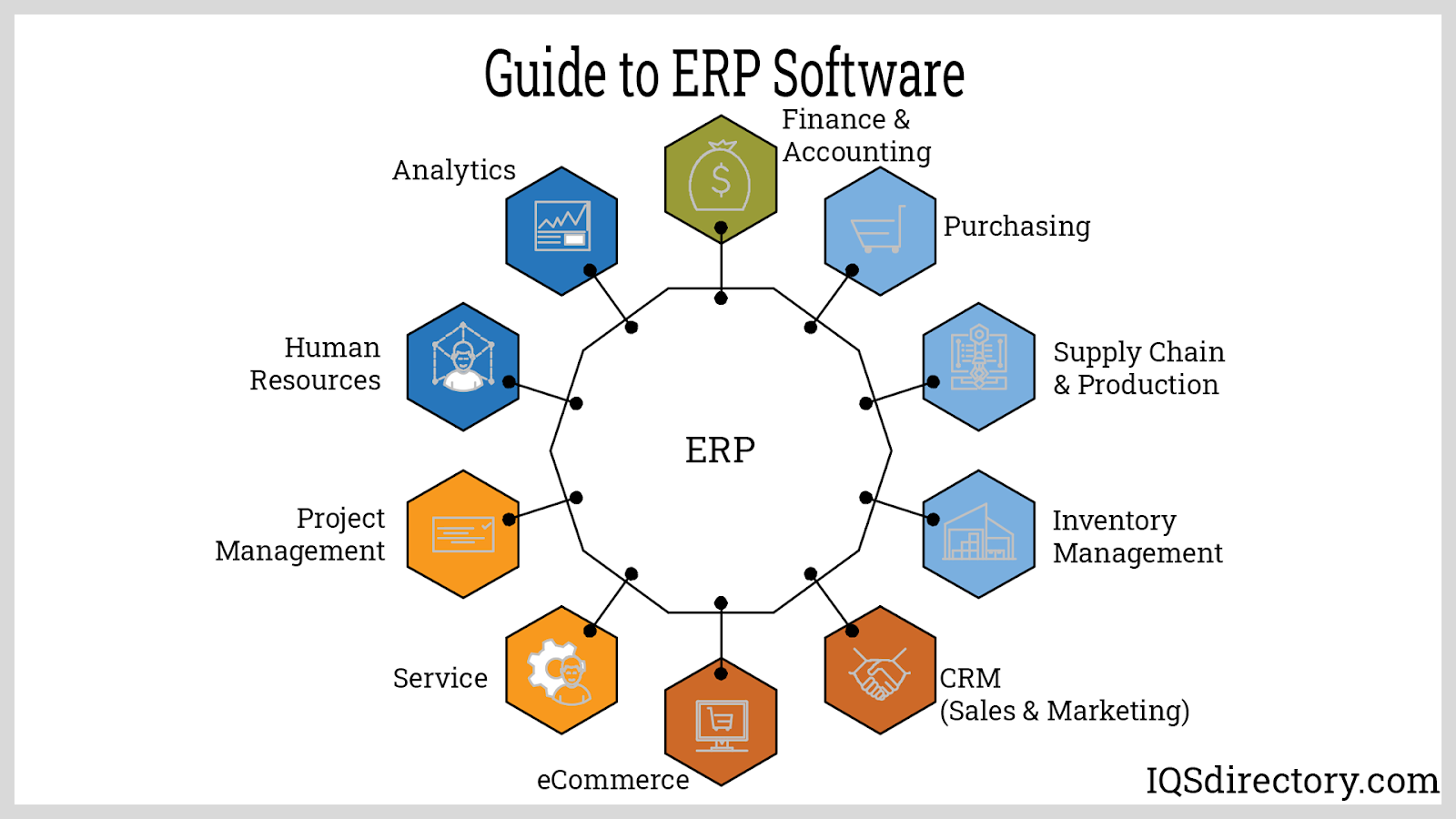

ERP software plays a crucial role in the manufacturing industry by helping businesses streamline their operations, improve efficiency, and make informed decisions based on real-time data. It integrates various processes and functions across the organization, providing a centralized platform for managing resources, production, inventory, sales, and more.

Main Features and Functionalities

- Inventory Management: ERP software allows manufacturers to track and manage their inventory levels in real-time, ensuring optimal stock levels and reducing the risk of stockouts or overstocking.

- Production Planning: Manufacturers can create detailed production schedules, allocate resources efficiently, and optimize production processes to meet customer demand and deadlines.

- Sales and Order Management: ERP systems enable manufacturers to automate order processing, manage sales orders, track shipments, and improve customer satisfaction through timely order fulfillment.

- Quality Control: ERP software helps manufacturers monitor product quality at every stage of the production process, identify defects, and implement corrective actions to maintain high product standards.

- Financial Management: With integrated accounting modules, manufacturers can manage their financial transactions, track expenses, generate financial reports, and ensure compliance with accounting standards.

Benefits of Implementing ERP Software

- Improved Efficiency: ERP software streamlines operations, eliminates manual processes, reduces errors, and enhances productivity across the organization.

- Enhanced Visibility: Manufacturers gain real-time insights into their operations, allowing them to make data-driven decisions, identify bottlenecks, and optimize processes for better performance.

- Cost Savings: By optimizing resource allocation, reducing inventory carrying costs, and minimizing waste, ERP software helps manufacturers cut operational expenses and improve profitability.

- Compliance and Risk Management: ERP systems help manufacturers comply with industry regulations, manage risks effectively, and maintain data security to protect sensitive information.

- Scalability: As manufacturing businesses grow, ERP software can scale with them, accommodating increased production volumes, expanding product lines, and adapting to changing market demands.

Key Modules in ERP Software for Manufacturing

ERP software for manufacturing typically includes several key modules that are essential for streamlining operations and increasing efficiency. These modules are specifically designed to address the unique needs of manufacturing companies, from inventory management to production planning and scheduling.

Inventory Management

Inventory management is a crucial module in ERP software for manufacturing as it helps companies keep track of raw materials, work-in-progress, and finished goods. By integrating inventory management into the ERP system, manufacturers can optimize inventory levels, reduce carrying costs, and prevent stockouts. This module also enables real-time visibility into inventory levels, making it easier to make informed decisions regarding production and procurement.

- Automated inventory tracking and replenishment

- Integration with suppliers for seamless procurement

- Forecasting tools to predict demand and optimize inventory levels

- Barcode and RFID technology for accurate inventory tracking

Production Planning and Scheduling

The production planning and scheduling module in ERP software for manufacturing plays a key role in optimizing production processes and maximizing efficiency. This module helps manufacturers create production plans, schedule jobs, allocate resources, and track progress in real-time. By using this module, manufacturers can improve production lead times, reduce bottlenecks, and increase overall productivity.

- Capacity planning to optimize resource utilization

- Real-time monitoring of production schedules and progress

- Sequencing of production tasks for efficient workflow

- Integration with other modules like inventory management and procurement

Implementation Process of ERP Software in Manufacturing

Implementing ERP software in a manufacturing environment involves several key steps to ensure successful deployment and adoption.

Steps in Deploying ERP Software in Manufacturing:

- Planning: Define goals, scope, and timeline for implementation.

- Selection: Choose the right ERP software that aligns with manufacturing processes.

- Customization: Tailor the ERP system to meet specific manufacturing needs.

- Data Migration: Transfer existing data into the new ERP system accurately.

- Training: Provide comprehensive training to employees on how to use the ERP software effectively.

- Testing: Conduct thorough testing to identify and resolve any issues before full deployment.

- Go-live: Launch the ERP system and monitor its performance in real manufacturing operations.

- Optimization: Continuously improve and optimize the ERP software to maximize its benefits.

Tips for Successful Implementation and Adoption of ERP Software:

- Engage stakeholders at all levels throughout the implementation process.

- Communicate clearly about the benefits and objectives of the ERP software to employees.

- Provide adequate training and support to ensure user proficiency and acceptance.

- Set realistic goals and expectations for the ERP system implementation.

- Regularly evaluate and adjust the ERP software to meet changing manufacturing needs.

Common Challenges Faced During ERP Software Implementation in Manufacturing:, Erp software for manufacturing

- Resistance to Change: Employees may be reluctant to adopt new processes and technologies.

- Data Integration Issues: Ensuring seamless integration of data from various sources into the ERP system.

- Cost Overruns: Unexpected expenses during implementation can impact the project budget.

- Lack of Executive Support: Without leadership buy-in, the ERP implementation may face roadblocks.

- Performance Issues: System slowdowns or downtime can disrupt manufacturing operations.

Customization and Integration Capabilities: Erp Software For Manufacturing

Customization and integration capabilities in ERP software for manufacturing play a crucial role in ensuring that the system aligns with the unique requirements of the industry. Let’s explore the various options available for customization and the process of integrating ERP software with existing systems and machinery on the manufacturing floor.

Customization Options in ERP Software

- ERP software for manufacturing typically offers customizable modules that can be tailored to specific manufacturing processes and workflows. This allows companies to adapt the system to meet their unique requirements and industry standards.

- Customization options may include configuring workflows, defining user roles and permissions, creating custom reports, and integrating third-party applications to enhance functionality.

- Companies can work closely with ERP vendors or consultants to identify areas that require customization and develop solutions that address their specific needs.

Integration Process of ERP Software in Manufacturing

- Integrating ERP software with existing systems and machinery on the manufacturing floor involves connecting the ERP system with various tools and equipment used in production.

- This process may require developing custom interfaces or using middleware to facilitate communication between different systems and ensure seamless data exchange.

- Integration enables real-time data sharing, improves visibility across the manufacturing process, and streamlines operations by eliminating manual data entry and reducing errors.

Importance of Seamless Integration

- Seamless integration between ERP software and other tools used in manufacturing operations is essential for maximizing efficiency, productivity, and profitability.

- Integrated systems enable better decision-making, optimize resource allocation, and enhance collaboration among different departments within the organization.

- By connecting ERP software with production machinery, inventory management systems, and other operational tools, manufacturers can achieve a more synchronized and streamlined production process.

Last Recap

In conclusion, ERP software for manufacturing is a game-changer that empowers businesses to thrive in a dynamic and competitive landscape. By streamlining operations, optimizing processes, and enhancing efficiency, this software sets the foundation for sustainable growth and success in the manufacturing sector.