Laser engraver software revolutionizes the design process with its advanced capabilities and seamless integration, offering a glimpse into a world of intricate and precise creations.

From optimizing material settings to maximizing workflow efficiency, this software is a game-changer in the realm of design.

Overview of Laser Engraver Software

Laser engraver software is a specialized program used to control laser engraving machines, allowing users to create intricate designs, patterns, and text on various materials. This software plays a crucial role in translating digital designs into physical engravings with precision and accuracy.

Features of Laser Engraver Software

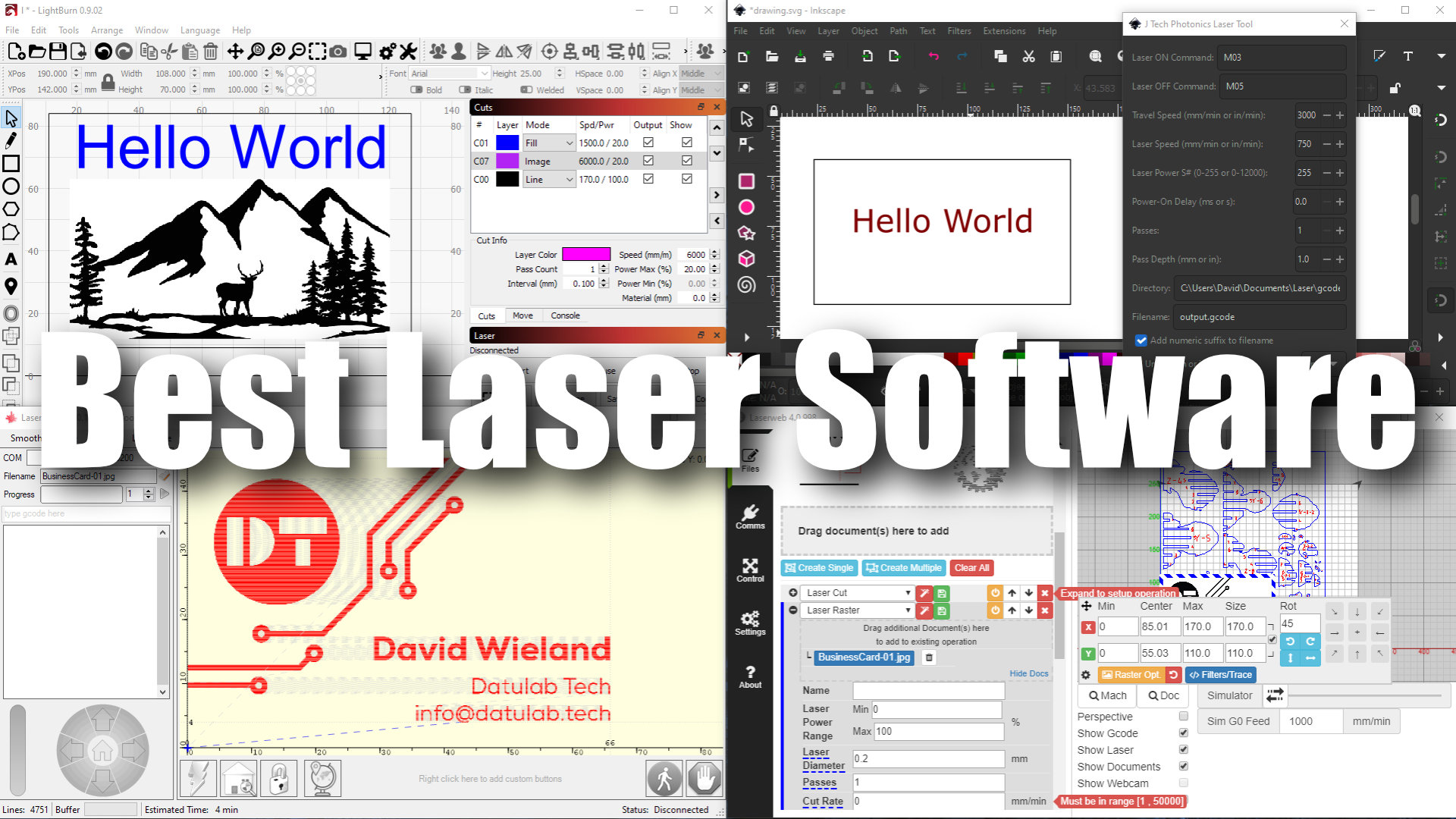

- Vector Graphics Support: Laser engraver software commonly supports vector graphics formats like SVG and AI, enabling users to create scalable and high-quality designs.

- Customizable Settings: Users can adjust parameters such as laser power, speed, and focal length to achieve different engraving effects on various materials.

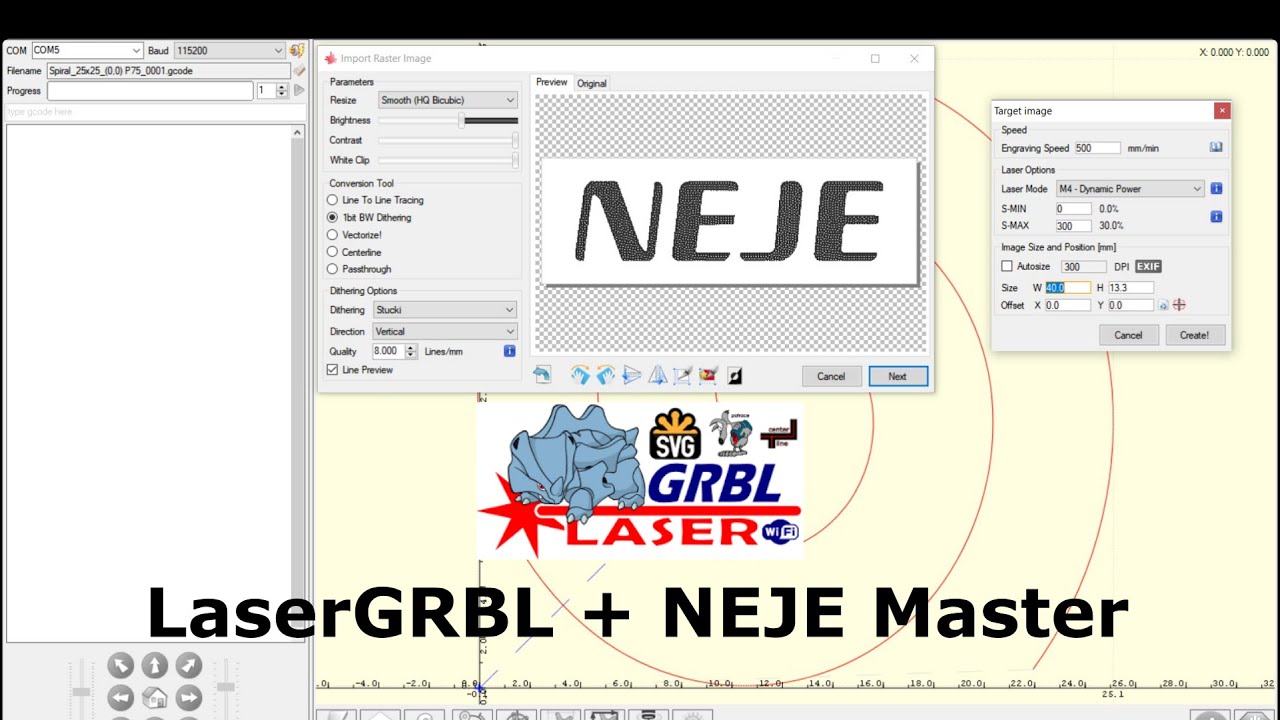

- Preview Functionality: Many laser engraver software programs offer a preview feature to visualize the engraving design before execution, helping users make necessary adjustments.

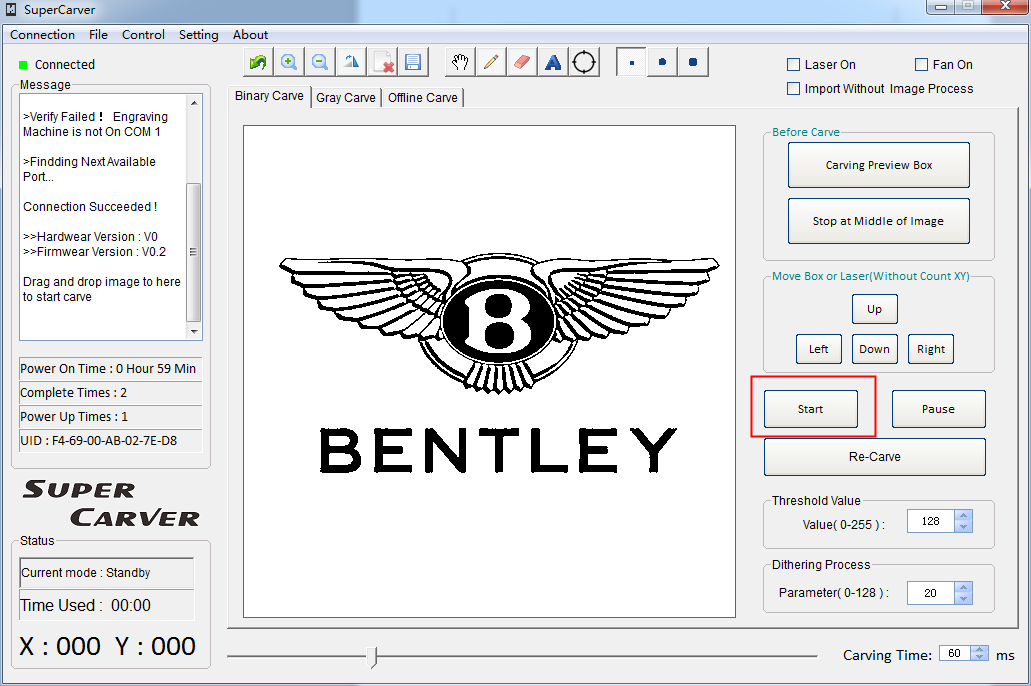

- Text and Image Editing Tools: These tools allow users to add text, images, shapes, and patterns to their designs, providing a range of creative options.

Popular Laser Engraver Software

- LightBurn: Known for its user-friendly interface and powerful features, LightBurn is a popular choice among laser engraving enthusiasts and professionals.

- GrblController: This open-source software is widely used for controlling CNC machines, including laser engravers, offering versatility and customization options.

- RDWorks: Developed by Ruida Technology, RDWorks is another commonly used software for laser engraving machines, known for its comprehensive set of features.

Compatibility and Integration

When it comes to laser engraver software, compatibility and integration play crucial roles in ensuring smooth operation and optimal results.

Operating System Compatibility

- Most laser engraver software is compatible with popular operating systems like Windows, macOS, and Linux.

- It is important to check the system requirements of the software to ensure it can run effectively on your operating system.

Integration with Design Programs

- Laser engraver software often integrates seamlessly with design programs such as Adobe Illustrator, CorelDRAW, and AutoCAD.

- This integration allows users to create and edit designs in their preferred design software and easily transfer them to the engraving software.

Tips for Seamless Integration

- Ensure that both the design program and laser engraver software are up to date to avoid compatibility issues.

- Use file formats that are supported by both the design program and engraving software to prevent any loss of data or formatting issues.

- Calibrate the settings of the engraving software to match the specifications of your hardware for accurate results.

- Regularly test the integration by sending small test files to the engraver to identify any potential issues before starting a large engraving job.

Design Capabilities

When it comes to laser engraver software, the design capabilities play a crucial role in creating intricate and detailed designs. These tools enable users to unleash their creativity and produce high-quality engravings with precision.

Design Tools Available

- Vector Drawing Tools: Laser engraver software typically offers vector drawing tools that allow users to create shapes, lines, and curves with precision.

- Image Import: Users can import images and convert them into vector formats for engraving.

- Text Editing: The software usually includes text editing tools to customize fonts, sizes, and styles for adding text to designs.

- Layer Control: Users can manage different design elements by organizing them into layers for better control and editing.

- Engraving Parameters: Software enables users to adjust engraving parameters such as speed, power, and depth to achieve desired results.

Comparison of Software Options

- Trotec’s JobControl: Known for its user-friendly interface and advanced design tools, JobControl offers a wide range of design capabilities for intricate engravings.

- Gravostyle: This software is popular for its extensive library of design elements and powerful editing tools, making it a top choice for detailed designs.

- LightBurn: LightBurn is favored for its compatibility with various laser engraving machines and its intuitive design tools for creating complex designs.

Examples of Intricate Designs

From intricate patterns and detailed portraits to intricate typography and complex geometric designs, laser engraver software can bring a wide range of artistic creations to life.

Material Settings and Customization: Laser Engraver Software

When using laser engraver software, one important aspect to consider is the customization of material settings. This feature allows users to optimize their engraving process for different types of materials, ultimately leading to better outcomes.

Customizing Material Settings, Laser engraver software

Customizing material settings involves adjusting parameters such as power, speed, and frequency to suit the specific material being engraved. Users can input the material type and thickness into the software, which then suggests optimal settings based on the selected material.

- Experiment with different settings: It’s important to test various combinations of power, speed, and frequency to find the ideal settings for each material.

- Consider the material properties: Different materials react differently to the laser engraving process, so it’s essential to adjust settings accordingly.

- Save custom settings: Once optimal parameters are found for a specific material, users can save these settings for future use, making the process more efficient.

Optimizing Settings for Different Materials

Each material requires specific settings to achieve the desired engraving results. For example, engraving on wood may require higher power levels compared to engraving on acrylic. It’s crucial to understand the characteristics of each material and adjust the settings accordingly to achieve the best outcome.

- Consult material guides: Many laser engraver software programs provide guides or recommendations for optimal settings for different materials.

- Start with default settings: If unsure about the optimal settings, users can begin with default settings provided by the software and make adjustments based on the results.

- Consider material thickness: Thicker materials may require different settings compared to thinner materials, so it’s essential to take the material thickness into account when customizing settings.

Importance of Material Customization

Customizing material settings is crucial for achieving the desired engraving outcomes. By fine-tuning settings based on the material being used, users can ensure precise engraving, avoid damage to materials, and enhance the overall quality of the finished product.

- Enhanced precision: Customizing settings allows for more precise engraving, resulting in clearer designs and sharper details.

- Preventing damage: Incorrect settings can lead to burnt or melted materials, so customizing settings helps prevent damage and wastage.

- Quality improvement: By optimizing settings for different materials, users can improve the overall quality of their engravings and create professional-looking products.

Workflow and User Interface

When working with laser engraver software, the typical workflow involves importing or creating a design, adjusting settings such as speed and power, previewing the engraving, sending the job to the laser engraver, and finally, overseeing the engraving process.

Comparison of User Interfaces

Different laser engraver software may have varying user interfaces, ranging from simple and intuitive layouts to more complex and feature-rich designs. Some software may prioritize ease of use with minimal options displayed upfront, while others may offer extensive customization features with a steeper learning curve. It’s essential to choose a user interface that aligns with your skill level and the complexity of your engraving projects.

Best Practices for Workflow Efficiency

- Organize your design files in a logical manner to easily locate and access them within the software.

- Utilize presets and templates for commonly used settings to streamline the setup process.

- Take advantage of grouping and nesting features to efficiently manage complex designs and elements.

- Regularly calibrate the laser engraver to ensure accurate and consistent results during the engraving process.

- Stay updated on software updates and new features to leverage the latest tools for improved efficiency.

Conclusion

In conclusion, laser engraver software empowers designers to unlock their creativity and achieve unparalleled precision in their projects, setting new standards for design innovation and efficiency.